Disassembly sequence of piston pumps is incorrect, not knowing which part to disassemble first, unable to start;

Parts of piston pumps are not marked according to the disassembly sequence, making it impossible to reassemble in order later;

Parts are disorganized after disassembly, and after a few days, parts are missing, making it impossible to reassemble;

...

Have you also had such an experience while disassembling a piston pump?Feeling a bit embarrassed?

Although disassembling a piston pump appears simple, there are many details that need attention during the process. Many colleagues, especially new ones, as well as some experienced repair technicians, have encountered such issues when disassembling piston pumps.

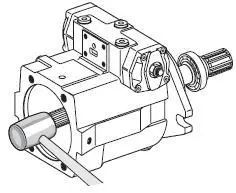

Today, based on my practical experience, I've summarized the correct disassembly method for a small hydraulic piston pump. This can be referred to for other brands and types of piston pumps as well. Hope it helps you!

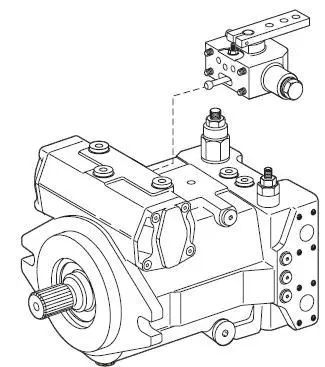

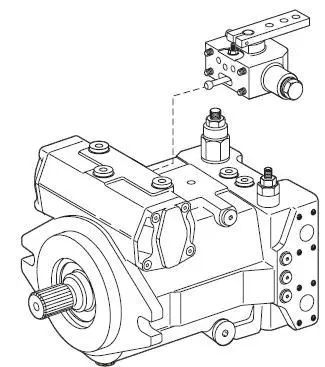

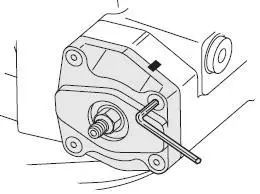

Disassembling the Small Hydraulic Piston Pump Control Device

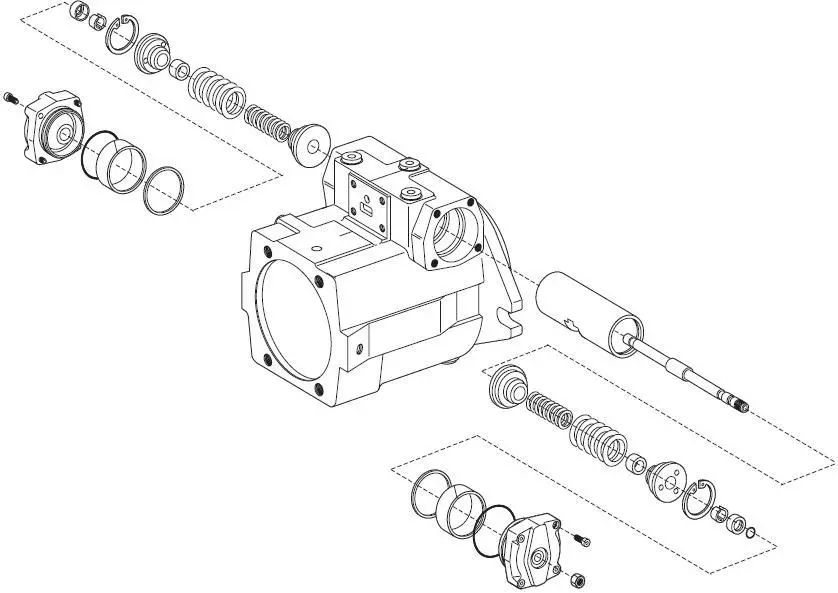

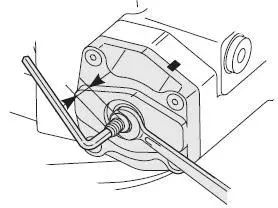

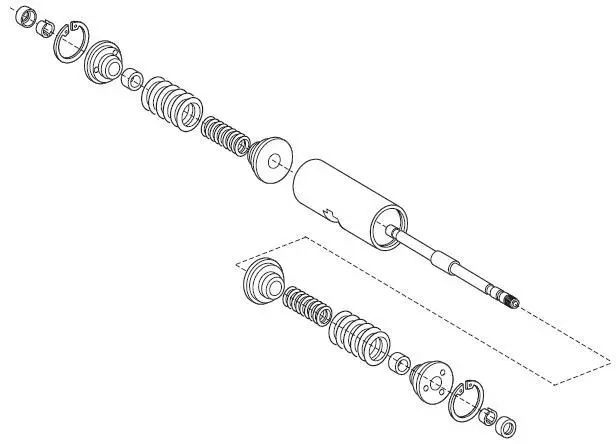

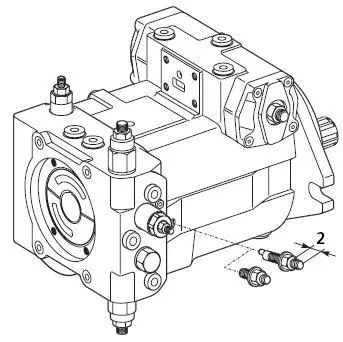

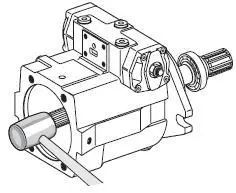

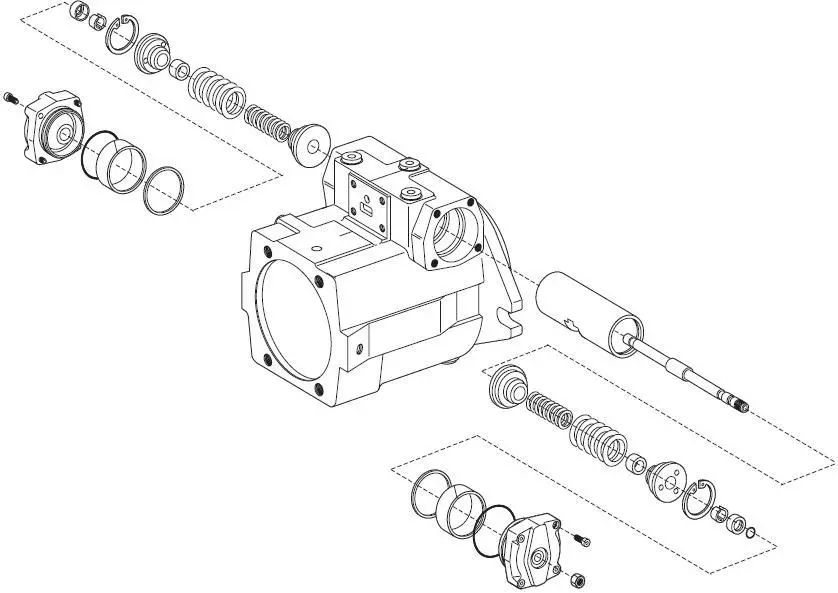

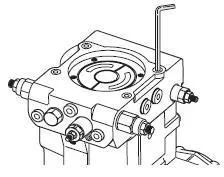

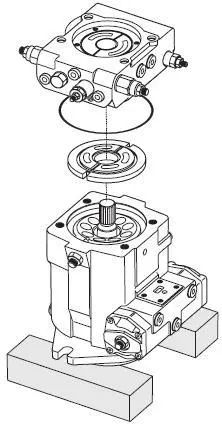

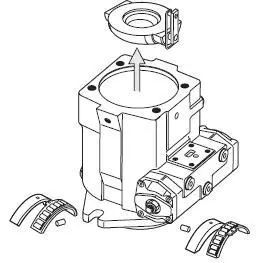

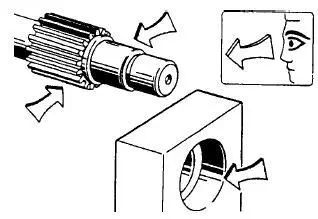

Exploded view of the control elements, as shown below:

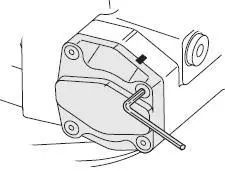

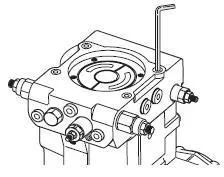

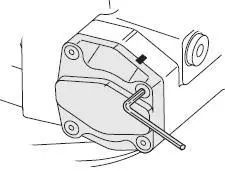

1. Loosen the fixing bolts

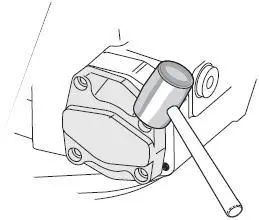

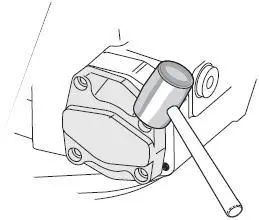

2. Use a hammer (brass or rubber hammer) to tap the back cover of the rotary body to loosen it and remove the back cover

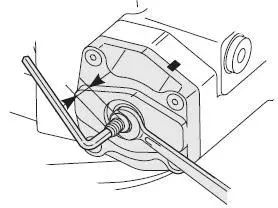

3. Mark the back cover, measure the protruding length of the bolts, and loosen the self-locking nuts

4. Remove the hex socket bolt

5. Hand-turn the bolt and remove the side cover (ensure hands are clean)

6. Remove the servo piston

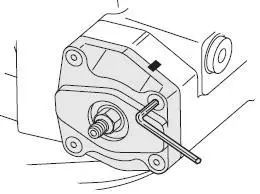

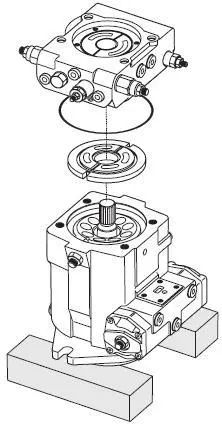

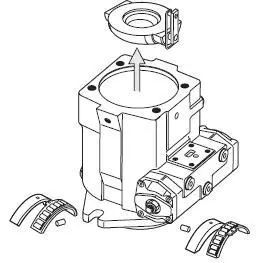

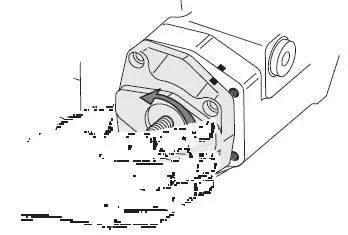

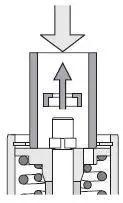

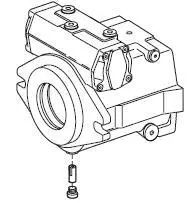

Exploded view of the servo piston, as shown below:

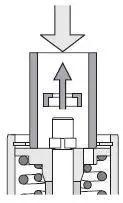

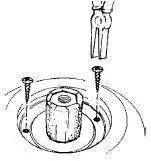

7. Use a special tool to compress the spring

8. Use circlip pliers to remove the circlip.

Note: There are compressed springs inside, be careful to prevent injury

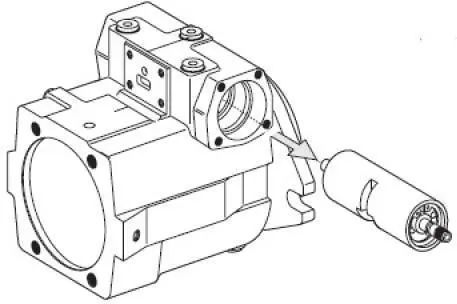

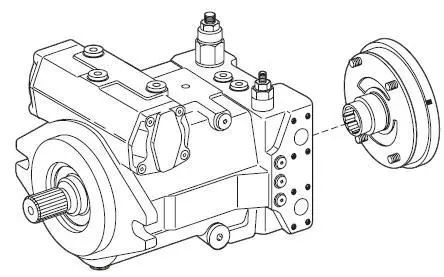

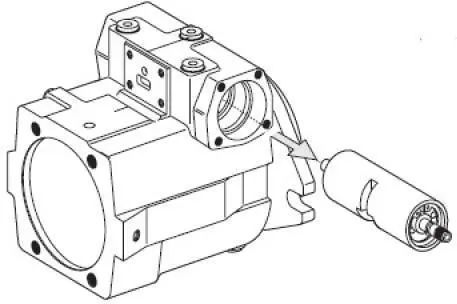

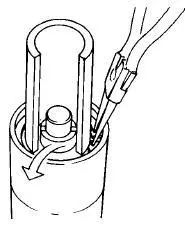

Disassembling the Small Hydraulic Piston Pump Charge Pump

Important: After disassembly, be sure to mark the assembly position to facilitate subsequent assembly

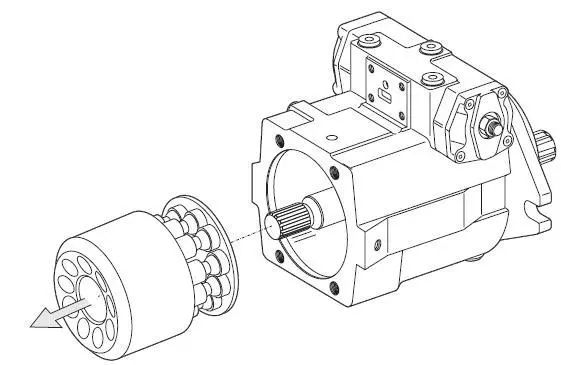

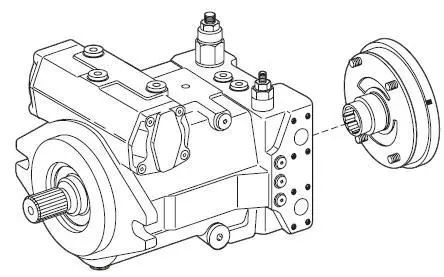

Disassembling the Small Hydraulic Piston Pump Main Body

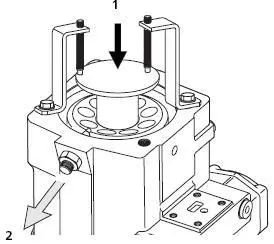

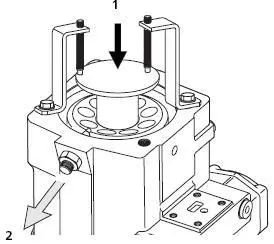

1. Mark the position of the hex socket bolts(1)

Record the position to which the bolts should be turned(2)

Turn the hex socket bolts to the marked position(3). This step is crucial.

2. Make marks, then remove the back cover(connecting block)

3. Remove the back cover and port plate

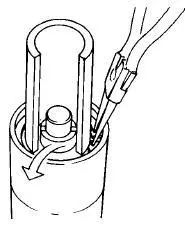

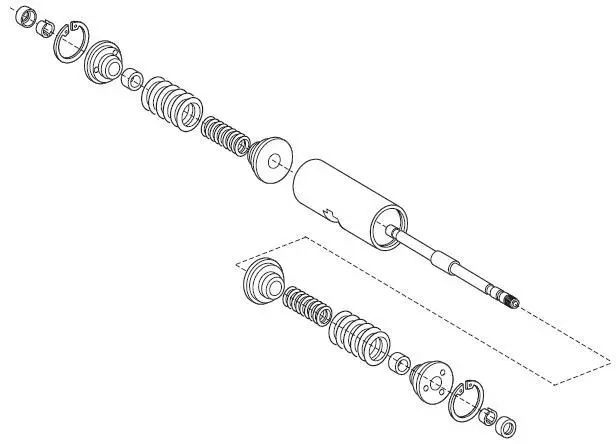

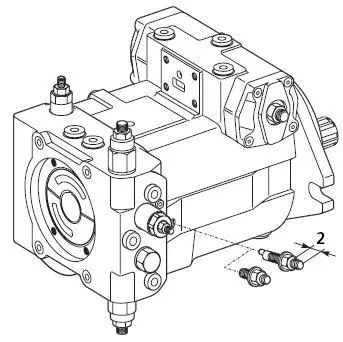

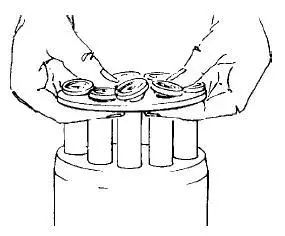

4. (1) Press down the cylinder body

(2) Remove the fixed hex socket bolts

(3) Remove the rotary body assembly

Note: Do not scratch the surface of the cylinder body

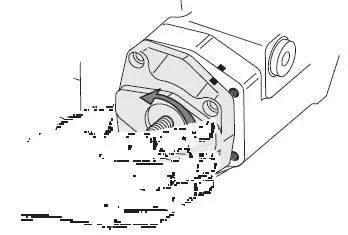

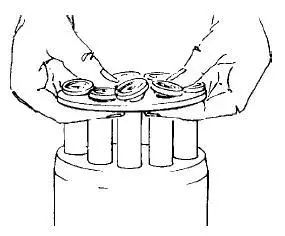

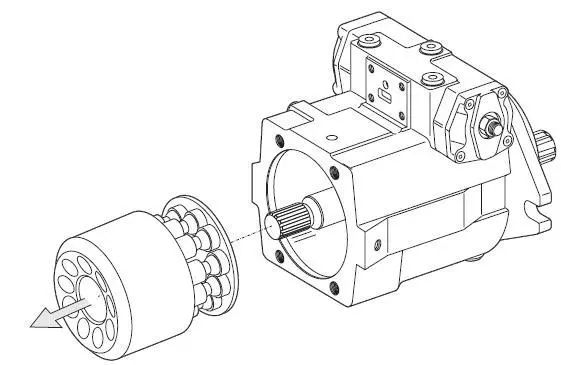

5. Remove the cylinder body and piston

When disassembling the cylinder body assembly, remove the pistons and return plates together with the compressed springs, and remove the ball joints.

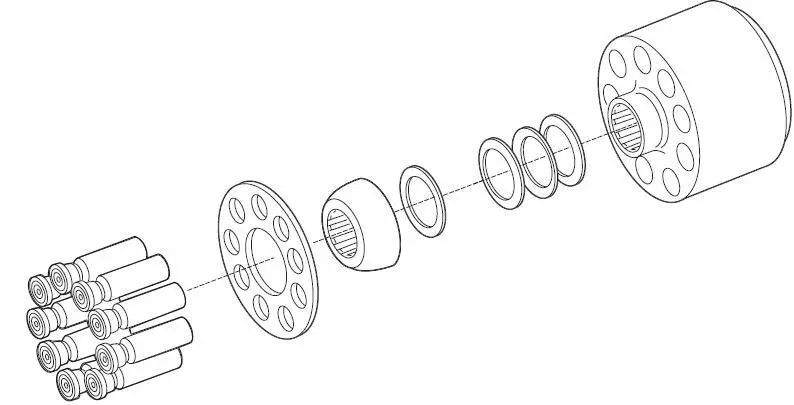

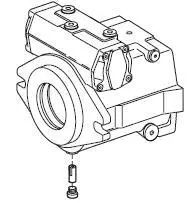

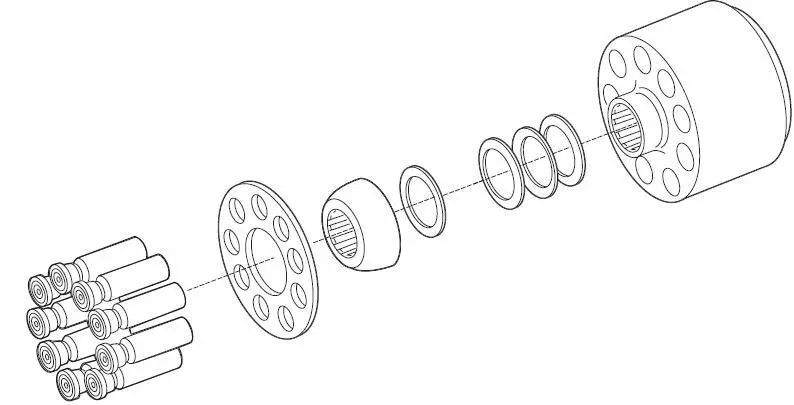

Exploded view of the cylinder body, as shown below:

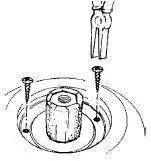

6. Use self-tapping nuts to screw into the uncovered metal parts (two places in total), then use pliers to pull out the seal.

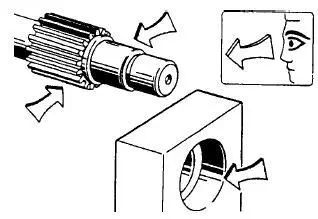

7. Use a soft hammer or brass rod to gently tap the shaft out.

8. Remove the rocker plate and the bearing.

9. Remove the locating pin of the swash plate bearing.

Disassembly Precautions for Small Hydraulic Piston Pumps

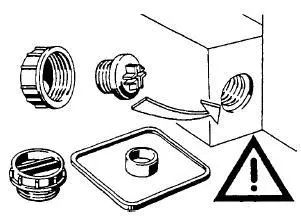

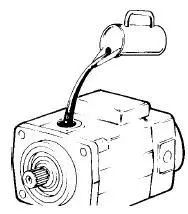

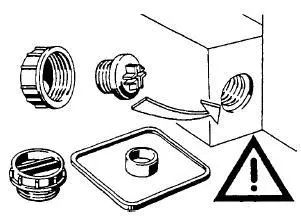

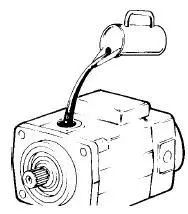

After assembly, all oil ports must be sealed to prevent impurities from entering the pump.

Remember: Seal all oil ports.

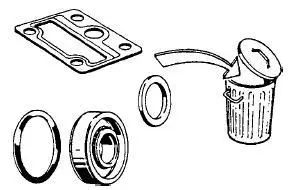

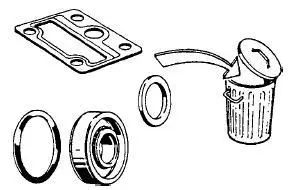

All O-rings can deform over time, and they might get damaged during disassembly. Therefore, all O-rings and seals must be replaced during maintenance.

Remember: Replace all seals.

All mating surfaces will experience varying degrees of wear after use, so inspect the wear condition thoroughly.

Remember: Check all mating surfaces for wear and repair the sealing surfaces.

During startup, if the coupling components of the rotating parts are insufficiently lubricated, they can wear or seize up in a very short time. Ensure that oil is added before starting!

Label the components of the small hydraulic piston pump according to the disassembly sequence and arrange them neatly.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu